Train Derailment

South Wales

Method of Treatment

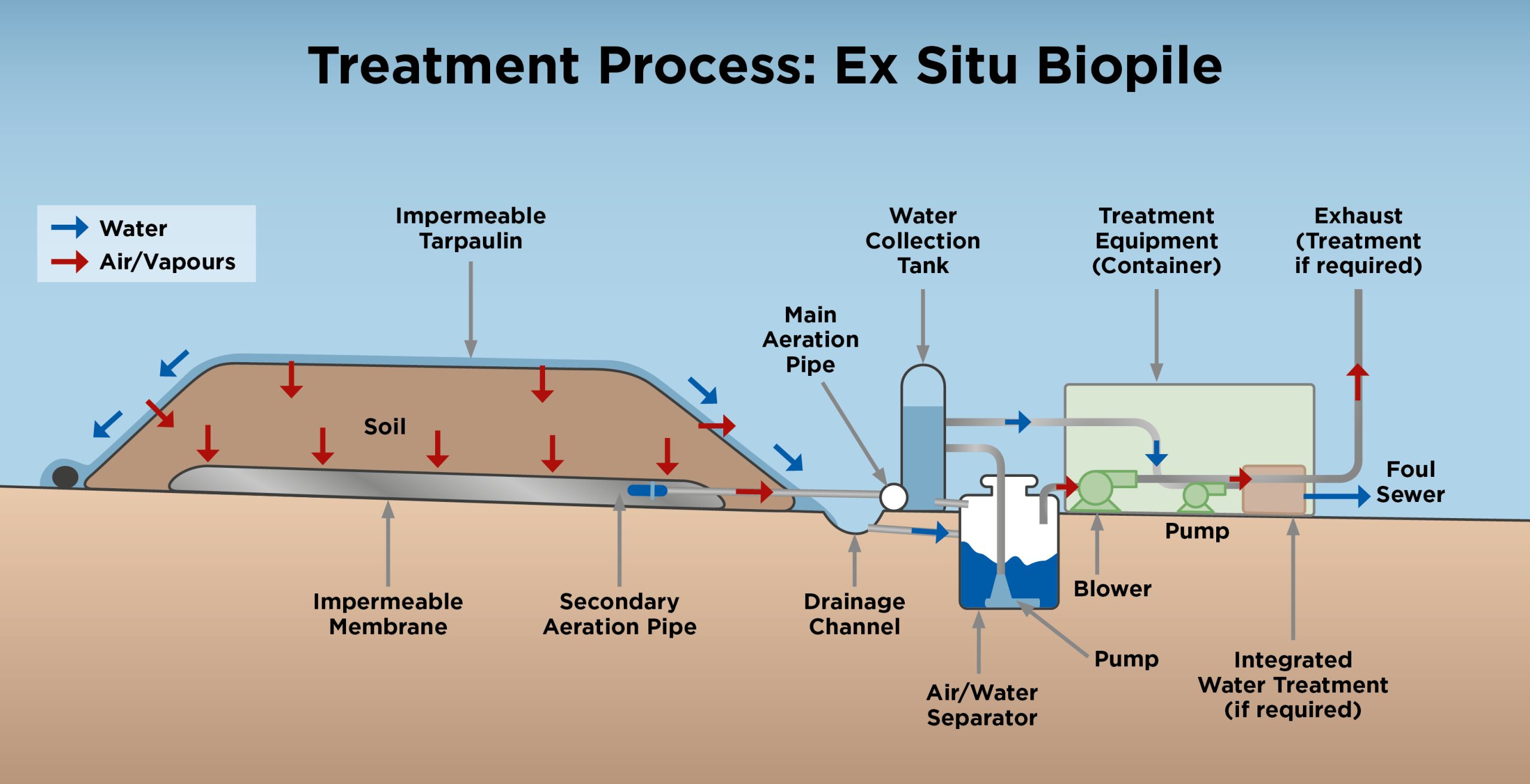

The treatment process of bioremediation provides optimal conditions to the bacteria naturally present in the soil, this promotes their development and increases their capacity to degrade organic pollutants.

The emergency response & remediation of large volumes of hazardous diesel impacted soils at our BIOGENIE UK Trecatti soil treatment facility in Merthyr Tydfil, South Wales. A major incident was declared following a fuel freight train derailment, spillage & subsequent fire at Llangennech, South Wales on the evening of 26th August 2020. The incident was national news due to the severity of the crash and subsequent release of fuel at the crash site.

Approximately 330,000 litres of diesel spilt on the crash site encompassing a site of international importance containing a site of special scientific Interest, Burry Inlet Special Area of Conservation, Ramser conservation site and on the edge of The Coal Authority’s Morlais Minewater Treatment Works. The emergency clean up works which included excavation of fuel impacted soils generated approximately 30,000 tonnes of hazardous soils requiring removal from the site. This project details the management, treatment and beneficial re-use of contaminated soils post treatment by BIOGENIE Remediation UK Limited.

- Waste assessment – Following extensive site investigation work and BIOGENIE Remediation UK Limited site visits, the impacted soils were assessed by our waste team and classified as hazardous by virtue of elevated hydrocarbons & acceptable for treatment at our permitted treatment facility at Trecatti, Merthyr Tydfil.

Time critical delivery – Due to the emergency situation required to decontaminate the site, reinstate the rail line & to deliver for our customer Gavin Griffiths Group, BIOGENIE Remediation UK Limited had to provide certainty we could accept the large volume of soil inputs estimated to be ~30,000 tonnes across 10 weeks in winter, including weekends and Christmas bank holidays.

FACILITY LOGISTICS / TREATMENT IN WINTER

- Haul road improvements to handle ~50 lorries/day during wet wintry conditions.

- New exit to the facility to manage increased traffic.

- Management of difficult high moisture content soils.

- Safely managing inputs of 1,000 tonnes per day.

- Real time on-site testing of hydrocarbons to optimise treatment.

- Extended openings, including weekends and bank holidays, 100% landfill diversion and recovery.

- In total 30,829 tones (1728) tipper loads) were delivered into BIOGENIE UK’s facility in ten weeks across the winter od December 2020 to February 2021

The contaminated soils were treated via bioremediation & 100% of the material was beneficially re-used in the site landfill restoration scheme post treatment.

The Event

A train en-route from Milford Haven refinery to Theale carrying 25 diesel tank wagons each carrying 100,000 litres of fuel suffered brake malfunction which derailed 10 wagons. Whilst the locomotive was able to travel several hundred metres up the tracks to safety the subsequent fire and explosion of the fuel wagons created a major emergency with a large volume of fuel spilled into the environment.

Following the news of the incident, the BIOGENIE Remediation UK Limited commercial team tracked the progress of the response & commenced discussions with the many parties involved. These included Natural Resources Wales (NRW), Network Rail, Adler and Allan, civils contractors and consultants.

Adler & Allan were subsequently named environmental & spill response contractor, our client for the project was Gavin Griffiths Group providing civils, groundwork, machinery, materials, transport and disposal services. BIOGENIE UK held discussions and meetings to provide our expertise in contaminated land remediation and soil treatment facilities. Subsequently agreements were reached regarding acceptance of the contaminated materials for treatment into our soil treatment facility (STF).

The project and exceptional response was critical to the local environment due to the large volume of fuel released into a site of international importance and this was reflected by the entire BIOGENIE UK team in mobilising our technical, operational and commercial teams to manage this project into our facility. To deliver for our customer we needed to provide certainty we could accept the large volumes of soil quickly in midwinter, estimated to be ~30,000 tonnes in ~10 weeks, including weekends and Christmas bank holidays.

Works at the facility included

- Detailed planning and logistics management during Covid 19

- Haul road improvements to handle the expected 50 lorries per day during wet wintry conditions

- A new exit to the soil treatment facility to manage increased traffic safely, managing inputs of over 1,000 tonnes per day

- Real time on-site testing of hydrocarbons to optimise treatment.

- Promptly validating and moving treated soils

- Exceptional team effort

We implemented a 6-day working pattern which started on site at 06:30 with 15 lorries arriving by 7am. The time critical logistics were often compounded by extreme weather which impacted the client’s site as well as the STF.(At around 360m (>1,000ft) elevation some would argue that the Trecatti facility is on a mountain, although officially it needs to be >2,000ft, either way when it is -11 degrees in the wind and snow, it feels like a mountainside and outdoor working is tough).

Despite the hard conditions exceptional work by our STF site manager and team meant we delivered for the client. In total the STF received 1,728 loads and 30,892 tonnes in just 10 weeks, across 2020 and 2021, allowing our customer to complete on programme.

BIOGENIE UK’s treatment method to remediate hazardous hydrocarbon impacted soils is via bioremediation. Once accepted at the weighbridge, this involves contaminated soils being assigned to a bioremediation treatment biopile. Each biopile has pipework underneath that draws clean air from the atmosphere through the material aiding the microbiological breakdown of contaminants. From here, the air is drawn through a blower unit and released through a Biofilter.

The Biofilter biologically treats the extracted vapour removing hydrocarbons and odours before the air is released back into the atmosphere. Whilst in treatment, the soils are mixed with amendments if required (also improving structure and aiding aeration) which help to increase and encourage bacteria to remain active, helping to optimise the breakdown of hydrocarbons & vastly reducing the hydrocarbon concentrations.

Samples are then collected to determine the progress of treatment and how long the soil will need to spend in treatment. Once sample results show hydrocarbon levels are reduced to a non- hazardous level and below the criteria for re-use: the material is ‘validated’ and is acceptable for beneficial reuse. Once validated and approved, by the restoration scheme technical manager, the material is beneficially re-used onto our partner Biffa’s landfill restoration scheme which is the final, above capping 300 mm of the landfill. This final restoration layer is generally planted as a nature reserve once the landfill site is completely capped.

Key benefits of the BIOGENIE Bioremediation process are:

- Material diverted from landfill void

- 100% of soils are beneficially reused/recycled in the restoration scheme

- Fully permitted by NRW

- Complete sustainability and environmental best practice techniques utilised

- No landfill tax applicable

In terms of economic benefit, hazardous soils into landfill void attract landfill tax to HMRC at the standard rate which is currently £126.15/tonne & at the time of the project £94.15/tonne. In landfill tax alone the 30,829 tonnes of contaminated soil would have tax implications of £2,902,550. Factoring gate fees & tax the total disposal costs into landfill would have been £4,289,855.

Our treatment costs to generate a restoration soil are a fraction of this at <20% providing project cost savings well in excess of £3m. In summary this is one of the largest and most challenging projects that BIOGENIE UK have been involved with in our near 20 years operating soil treatment facilities and we are proud to have supported our customer in these critical emergency clean up works. The environmental and social impact could have been catastrophic, the overall response from all parties was exemplary and we feel BIOGENIE UK’s contribution hugely benefitted the remediation operation and reduced the environmental impact with added economic benefits.

Unit 8, Commerce Park, Brunel Road, Theale, READING, RG7 4AB

Columbus House, Village Way, Tongwynlais, CARDIFF, CF15 7NE

Chadwick House, Birchwood Park, Risley, WARRINGTON, WA3 6AE

© 2025 Biogenie Remediation UK Limited